Content

The COGS calculation process allows you to deduct all the costs of the products you sell, whether you manufacture them or buy and re-sell them. List all costs, including cost of labor, cost of materials and supplies, and other costs. The formula above shows you the cost of goods manufactured is a component in the COGS calculation.

The cost of goods manufactured (COGM) is a metric that calculates the total cost of producing finished goods during a specific period. This calculation includes direct materials, direct labor, and manufacturing overhead. You can find the number of hours worked by each employee in the accounting period in the employee records. Multiply the number of hours worked by the employee’s hourly rate of pay to determine the labor cost for that employee. Take the sum of the labor cost for all employees to find the direct labor cost incurred by the manufacturer in the accounting period. Manufacturing costs refer to any costs incurred during the process of manufacturing a finished product and include the 1) cost of raw materials, 2) direct labor, and 3) overhead costs.

Cost of goods manufactured components

The cost of goods sold is considered an expense when looking at financial statements. That’s because it’s one of the costs of doing business and generating revenue. Ending inventory costs are usually determined by taking a physical inventory of products or by estimating. You most likely will need a tax professional to calculate COGS for your business income tax return. But you should know the information needed for this calculation, so you can collect all the information to include in this report. Say, a furniture manufacturer has $100 in stock of materials at the start of the period.

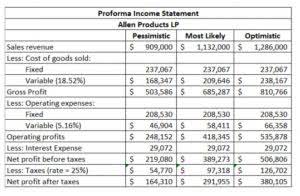

- The profitability picture gained from total manufacturing cost will also govern other strategies too, such as your approach to sales and pricing.

- Because when money is involved every calculation needs to be extra carefully done.

- At the end of the period, the finished product’s costs are presented in the finished product inventory.

- However, what should we include into manufacturing overhead is a complicated matter and doesn’t have a certain answer.

- It includes the cost of the raw materials and labor used in producing goods and any additional costs directly attributable to the production process, such as factory overheads, utilities, and depreciation.

It may also shine a light on costs that have, over time, become extortionate without you realising. This newfound visibility around spend could lead to a renegotiation with suppliers, to attain cheaper deals. Or you may research cost of goods manufactured formula some other potential partners, who can provide you with a better price (whilst supplying you with equally good materials). Meticulously keeping track of costs should be a task that is highly prioritised by all manufacturers.

Basic Cost of Goods Sold Formula

If it is a product cost, further indicate if the cost is direct materials, direct labor, or manufacturing overhead. Then determine if the product cost is a prime cost and/or a conversion cost. The cost of goods manufactured in three steps first direct material used is calculated, second total manufacturing costs incurred, and then the cost of goods manufactured is calculated. Goods manufactured refer to products produced by a company or manufacturer through a series of processes, using raw materials, components, and labor, to create finished products for consumers or other businesses.

What is the COGS of a manufacturing company?

Cost of goods sold (COGS) refers to the direct costs of producing the goods sold by a company. This amount includes the cost of the materials and labor directly used to create the good. It excludes indirect expenses, such as distribution costs and sales force costs.

Firstly though, you should be certain you know exactly what each aspect means. A) You tell your brother that your company will report earnings significantly above financial analysts’ estimates. Suppose a manufacturer is attempting to calculate its cost of goods manufactured (COGM) for 2021, its most recent fiscal year. For example, a manufacturer could intentionally produce units in advance in anticipation of a spike in seasonal demand.

Connect With a Financial Advisor

This formula will leave you with only the cost of goods that were completed during the period. The cost of goods manufactured in the calculation of the total production cost of the company at a specific point in time. As the name suggests, the COGM calculates the total manufacturing cost incurred on a product that has been manufactured and is ready to be sold. It considers all the expenses as direct material, direct labor, and factory overheads incurred on producing the goods.

If your COGM is higher than your selling price, then you aren’t making a profit on each item sold — and this can be bad news for your business. If you don’t know how much COGM you have, you won’t be able to make informed decisions about pricing or product development. Total manufacturing cost (TMC) is the total cost of all the materials and labor that go into making products for sale. Adding beginning WIP inventory to the total manufacturing cost, the new sum is obtained. It may seem obvious, but by being aware of all the expenses involved in your manufacturing operation, it becomes more possible to reduce these costs. Total manufacturing costs could highlight expenses that are completely unnecessary (and can therefore be eradicated completely).